What are Different Types of Fixtures in Manufacturing?

What are CNC fixtures in manufacturing?

A fixture is a work-holding or support device used in the manufacturing industry. CNC fixtures are used to securely locate and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability.

Different types of fixtures are:

1. Milling fixtures

2. Turning fixtures

3. Plate fixtures

4. Welding fixtures

5. Drilling fixtures

Let’s talk about them in detail

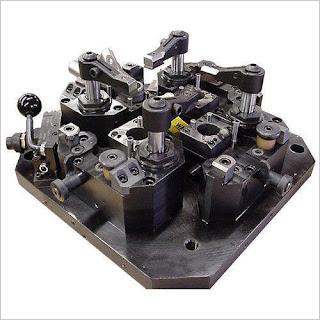

1. Milling fixtures

Milling operations tend to involve large, straight cuts that produce many chips and involve varying force. Locating and supporting areas must usually be large and very sturdy in order to accommodate milling operations.

Important elements are:

Base : A heavy base is the most important element of a milling fixture. It is a plate with a flat and smooth under face. The complete fixture is built up from this plate. Keys are provided on the under face of the plate which are used for easy and accurate aligning of the fixture on the milling machine table.

Blocks : it is vital to set the cutters and to ensure optimum setting, setting of blocks is required. The setting block is fixed to the fixture. Feeler gauges are placed between the cutter and reference planes on the setting block so that the correct depth of the cut and correct lateral setting is obtained.

2. Turning fixtures

These fixtures are generally mounted on the nose of the machine spindle or a face-plate, and the work-pieces held them.

Whenever necessary, the fixture may have to be provided with a counterweight or balance the unbalanced fixture.

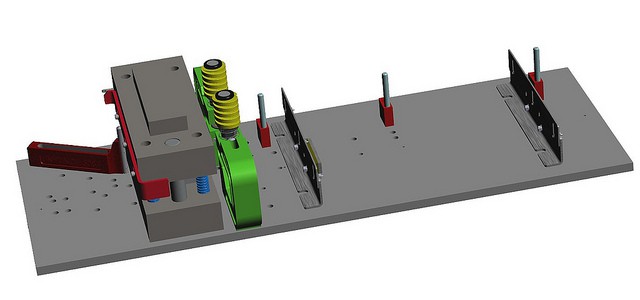

3. Plate fixture

They are the most basic and adaptable form of fixtures. The basic fixture is made from a flat plate that has a variety of clamps and locates to hold and locate the part. The simplicity of this fixture makes it useful for most machinery operations.

4. Welding fixtures

Welding fixtures are carefully designed to hold and support the various components to be welded in proper locations and prevent distortions in welded structures.

For this, the locating element needs to be carefully; clamping has to be light but firm, placement of clamping elements has to be clear of the welding area. The fixture has to be quite stable and rigid to withstand the welding stresses.

5. Drilling fixtures

Drilling fixtures cover a wider range of different designs and procedures than milling fixtures. Though work-holding for drills is more often provided by jigs, fixtures are also used for drilling operations.

Two major components of drilling fixture are:

1. Holes

2. Bushing

Holes are often designed into drilling fixtures, to allow space for the drill bit itself to continue through the work-piece without damaging the fixture or drill, or to guide the drill bit to the appropriate point on the work-piece.

Bushings are simple bearing sleeves inserted into these holes to protect them and guide the drill bit.

.jpg)

Comments

Post a Comment