Different Parts of the Punching Machine and their Functions

.jpg)

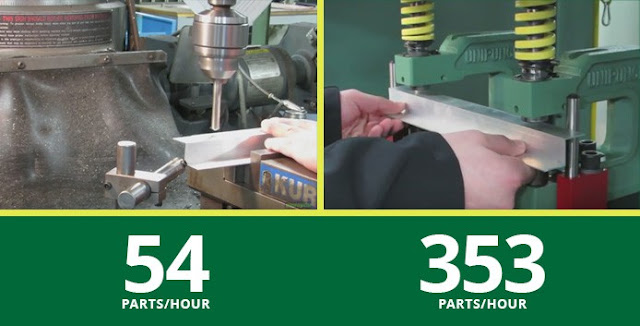

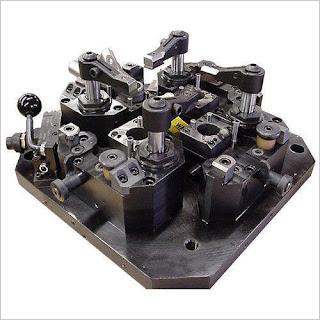

What is a punching machine? Punching is the process of creating custom holes in metal sheets, and thus, the punching machine is a very important machine for the metal industry. It can reduce your fabrication time and increase your efficiency, so it's worth it to invest in a machine. The uses of the punching machine are immense, and it is important to ensure that you have the best machine for your requirements. The design plays a major role in the efficiency of the machine, and if you are buying a new punching machine, it is important to be aware of the best designs on offer. Parts of Punching Machines and Their Function Punch and Die. Punches and dies are a type of cutting tool equipment utilized in the high-heat metal forming process known as hammering and punching. The cutting body needs a "punch" to act as a pusher, and the punch pushes into the die as a secondary item. Strippers Strippers and punches are a common combination in dies. The Stripper, as it...