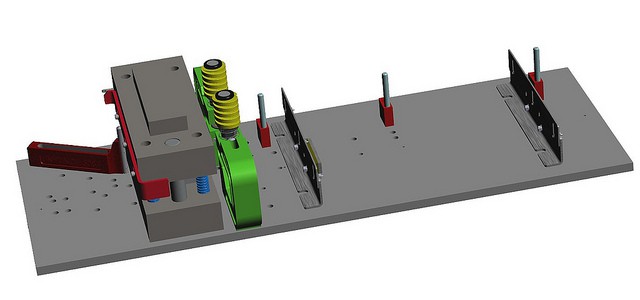

Different Parts of the Punching Machine and their Functions

What is a punching machine?

Punching is the

process of creating custom holes in metal sheets, and thus, the punching

machine is a very important machine for the metal industry. It can reduce your

fabrication time and increase your efficiency, so it's worth it to invest in a

machine.

The uses of the

punching machine are immense, and it is important to ensure that you have the

best machine for your requirements. The design plays a major role in the

efficiency of the machine, and if you are buying a new punching machine, it is

important to be aware of the best designs on offer.

Parts of Punching Machines and Their Function

Punch and Die.

Punches and dies are a type of cutting tool equipment utilized in the high-heat metal forming process known as hammering and punching. The cutting body needs a "punch" to act as a pusher, and the punch pushes into the die as a secondary item.

Strippers

Strippers and punches are a common combination in dies. The Stripper, as its name indicates, is a tool that was used in stamping to hold and subsequently remove the finished material from the punch.

Punching Guide

Punching guides are circular parts that are typically attached to the upper mold holder and utilized in combination with the guide pillar fixed in the lower mold holder to provide precise guidance for the relative motion of the top and bottom mold holder.

Head

A piece that effectively accepts the force of the puncher and transfers it to the driver and punches the body. Adjust the punch length by rotating the small diameter tool.

Spring

The main function of the die spring is to apply pressure in order to keep the target material in place while the punch breaks open, withdraws, or strips off. Use springs made of coil, urethane, disc, and other materials.

Punching Driver

The driver of the punching machine is in charge of running the combined punching machine and keeping the protection features in good working order.

Retainer

Guides are attached to the punching machine, which helps hold the spring.

Canister Spring

The combination of the head, spring, and retainer collar is known as the "Spring Canister. It is responsible for the length of the tool.

Ram

Because it

interacts directly with the work piece, this is the press's main functional

component. The ram has a predefined depth of cut and intensity that it uses to

move upwards and downwards between its tracks.

The stroke is the

name for this up-and-down movement. A power source, such as an engine, is built

within the crown and maintains the ram's upward and downward motion.

According to your needs, you can change the RAM's intensity and stroke length. The punch is fastened to the ram's base.

Conclusion

The Punching

Machine also known as a custom hole punch is an electronic machine that allows

you to punch a shape in different materials at a faster pace. It can be

controlled by the foot pedal or manually. This will help in doing industrial

work much faster and more efficiently by making use of the punching machine.

The automotive industry is where they are most frequently used. This can also

be used in other fields, such as construction, architecture, and many more.

Every part plays an important role in the whole process.

.jpg)

.jpg)

Comments

Post a Comment