5 Advantages of Pipe Punching Tool

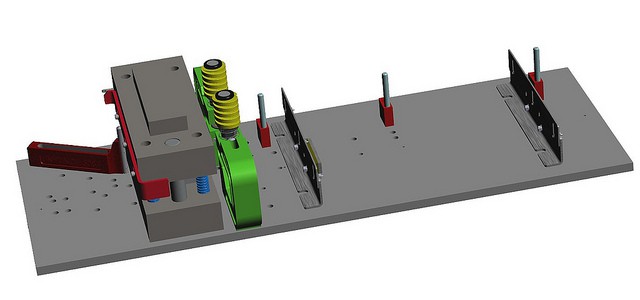

The pipe punching tools are suitable for a wide range of projects, including tank, pipeline, and power plant building. As a result, steel professionals may find these powerful, precise, and efficient tools to be a worthwhile investment. A pipe punching tool is typically used to punch through pipes, but they can also perform other tasks such as angle, slotting, marking, notching, and hole marking, depending on the machine.

Many major businesses have a fully pipe punching tool, and the roll-to-roll fully active punching machine may effectively share the fully active screen printing machine's next operation, resulting in streamlined automatic production and significant center reduction. In this article, we will discuss the advantages of pipe punching tool.

1. Streamlining ProcessesMetal shavings and imperfections can occur when cutting a tube with a physical blade, necessitating additional cleaning and shaping processes. Not only are the edges near-flawless when employing a pipe punching tool, but the slag from the cutting operation may also be easily collected using a waste collection drawer.

Many laser cutters have automatic loading, aligning, and unloading features, which eliminates the need for humans to execute multiple tasks.

2. Wide Range of Cutting Techniques

Laser cutting, like many other operations, benefits from CNC machinery's high level of control and precision. In addition to vertical cuts, laser pipe punching tool may perform angle, slots, etchings, bevel cuts, and more, depending on the equipment.

Many of these jobs can be accomplished with traditional laser cutters, but they aren't built to deal with cylindrical materials.

3. Stronger Tube Ends

Aside from making a cleaner punch, another benefit of using a pipe punching tool is that the cut is made without the need of mechanical force. Physical force is typically used by a CNC punching machine to break through the material being cut, creating tension on the surrounding material and potentially weakening it. Because the pipes were cut with a laser cutter, they are likely to be stronger on both ends.

4. Specialist Purposes

If your company receives a lot of requests for custom-shaped tubes, a pipe punching tool will improve performance and efficiency, allowing you to produce more custom-cut tubing in less time.

The machine is an excellent example, providing a wide range of pipes and profile punching options for a variety of industrial and application needs in the offshore, lifting, agriculture, pipelines, power plants, steel construction, and shipbuilding industries.

5. Seam Detection

Many modern pipe punching tool contain seam detection software, as well as cameras and light sources to discern seams inside and outside the tube. The machine will rotate the tube once it has been discovered to eliminate any potential problems. These are just some of the benefits that contemporary pipe laser cutting equipment provides to companies of all sizes.

.jpg)

Comments

Post a Comment