6 Advantages of Hydraulic C Frame Punch

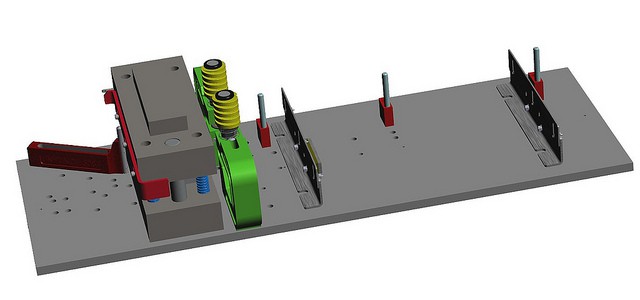

The Hydraulic C-frame punch presses are built to take up less floor area than traditional metalworking machinery while still providing good functionality and low stroke deflection. C-frame presses, like other hydraulic presses, are incredibly versatile and can be used in a variety of industries. The wide-open, three-sided accessibility and portability of hydraulic c frame punch are popular.

Hydraulic presses with C-frame frames are very frequent. These presses are named for the fact that they are fashioned like the letter "C," although they are also known as "gap-frame presses." We will learn about the application and benefits of hydraulic c frame punch in detail in this article.

1. Much Lower Operating Costs

The hydraulic c frame punch presses are relatively simple, and the huge cost savings over mechanical presses in comparable capacities may surprise you. The number of moving parts is small, and they are all properly lubricated by a pressurized oil flow. These parts are not only affordable, but they can also be replaced without dismantling the machine. As a result, there will be more uptime and decreased maintenance expenses.

2. Greater Versatility

Within its tonnage range, a single hydraulic c frame punch can perform a wide range of tasks. Deep draws, shell reductions, urethane bulging, shaping, blank and piercing, stake, punch, press fitting, straightening, and assembly are all examples of common processes. Powered metal forming, abrasive wheel forming, bonding, broaching, ball sizing, plastic and rubber compression, and transfer molding are just a few of the applications.

3. More Compact

A 20-ton hydraulic c frame punch press is typically eight feet tall, six feet deep, and two feet wide. A 200-ton press is just around ten feet tall, nine feet deep, and three feet broad. The 200-ton press, with ten times the capacity, only takes up 50% more floor space. Hydraulic presses are becoming less expensive than mechanical presses.

4. Quiet

The hydraulic c frame punches are quieter than mechanical presses since they have fewer moving parts and don't have a flywheel. Even when the pump is running at full capacity, correctly sized and placed pumping devices meet or exceed current Federal noise limits. A hydraulic ram can be regulated to go slowly and silently through the operation.

5. Lower Tool

Costs

If they are designed to withstand a particular load, there is no risk of overloading harming them. Tools, not presses, can be sized to bear the weight of a specific job. The press's pressure can be adjusted to suit the job. Longer tool life is facilitated by the absence of impact, stress, and vibration.

6. Safety

No manufacturer will (or should) claim that hydraulic c frame punch presses are safer than mechanical presses when it comes to safety. If the controls and safety mechanisms built into these types of machinery are used appropriately, they are planned and manufactured to be safe. The controls are non-tie down, anti-repeat, dual palm button controls. Because of the design of the guards, as well as other safety mechanisms, interlocking is quite simple.

Conclusion

C-frame presses are designed to take

up less space on the floor than conventional metalworking machinery while still

delivering excellent functionality and low stroke deflection. C-frame presses,

like other hydraulic c frame punch presses, are extremely adaptable and can be

utilized for a wide range of applications in a variety of industries.

.jpg)

Comments

Post a Comment