All about Hydraulic Presses & Hydraulic Press Die Manufacturers

We all know how much competitiveness exists in the hydraulic press market. Based on the demands of your application, manufacturers decide on factors like material design, load restrictions, and configuration when building a hydraulic press. Stainless steel is typically used in the design of hydraulic presses by manufacturers. In this post, you will learn everything about hydraulic press and hydraulic press die manufacturers.

What

Is a Hydraulic Press?

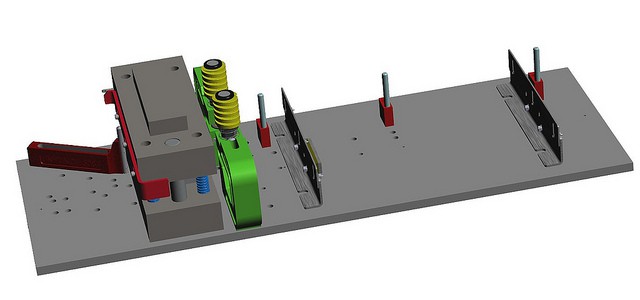

A hydraulic press is a mechanical tool that shapes, deforms, and arranges various kinds of metals, plastics, rubber, and wood using the static pressure of a liquid. The mainframe, power system, and controls make up the hydraulic press's mechanism. In a hydraulic press, a piston that functions as a pump to generate mechanical force applies pressure to a liquid.

Hydraulic

Press Working

When a double-acting piston is pressed into hydraulic fluid, a hydraulic press is initiated. The fluid is pushed into a larger cylinder where more force and pressure are applied by the compressive force inside the tiny hydraulic cylinder. The fluid is forced back into the smaller piston cylinder by the larger piston's action.

The hydraulic press's anvil is driven downward onto a workpiece that is bent into the correct shape by the increasing pressure produced by the flow of fluid between the two pistons. The pressure is released after the movement is finished, and the anvil then resumes its initial position.

Hydraulic

Press Benefits

Because they can exert greater force than mechanical presses, machine presses, or pneumatic presses, hydraulic presses are among the most popular and effective types of presses on the market. They also have advantages like-

●

Low

starting expenses

●

Low

maintenance prices

●

Simple

operation

● No operation noise

How

do Hydraulic Press Die Manufacturers Customize it?

As mentioned above, while designing a hydraulic press, manufacturers customize it with certain material designs, load limits, and configurations. Due to stainless steel's strength, durability, resistance to corrosion, and abrasion resistance, manufacturers typically use it in the construction of hydraulic presses.

Various strong materials including brass, aluminum, and other steel alloys may also be used. Manufacturers of hydraulic presses have a great deal of control over the maximum ton loads that can be handled by their machines. They can design presses specifically to handle loads ranging from one ton to more than 10,000 tons.

Manufacturers typically select between single-station and multi-station layouts when it comes to configurations. Single-station presses contain a tabletop and a single pair of press tools (a die and a punch). On the other hand, multi-station presses are made up of several different sets of press machine tools.

Use

of a Hydraulic Press

The hydraulic press is a significant component of numerous industrial and production processes. Hydraulic presses are a crucial component of contemporary industrial operations, being used for everything from the shaping and manufacturing of machine components to the crushing and compacting of trash and debris.

The idea of compressive force, which is produced by pistons using pressure from an incompressible liquid to produce mechanical force, is the foundation for the use of hydraulic presses. A manual hydraulic press can exert a few tons of force, while a motor-driven press can exert thousands of tons. These are the uses of the hydraulic press-

●

Manufacturing

●

Powder Compacting

●

Scrap baling

●

Production of ceramics

●

Laboratory

●

Military

● Concrete testing

Conclusion

Make a list of manufacturers with a track record of providing

top-notch service. Choose three or four people you believe will be able to best

meet your needs while keeping in mind your parameters. Then, get in touch with

each of them and let them know your needs, queries, and worries. Select the

manufacturer you believe will best meet your needs, then get going.

.jpg)

Comments

Post a Comment